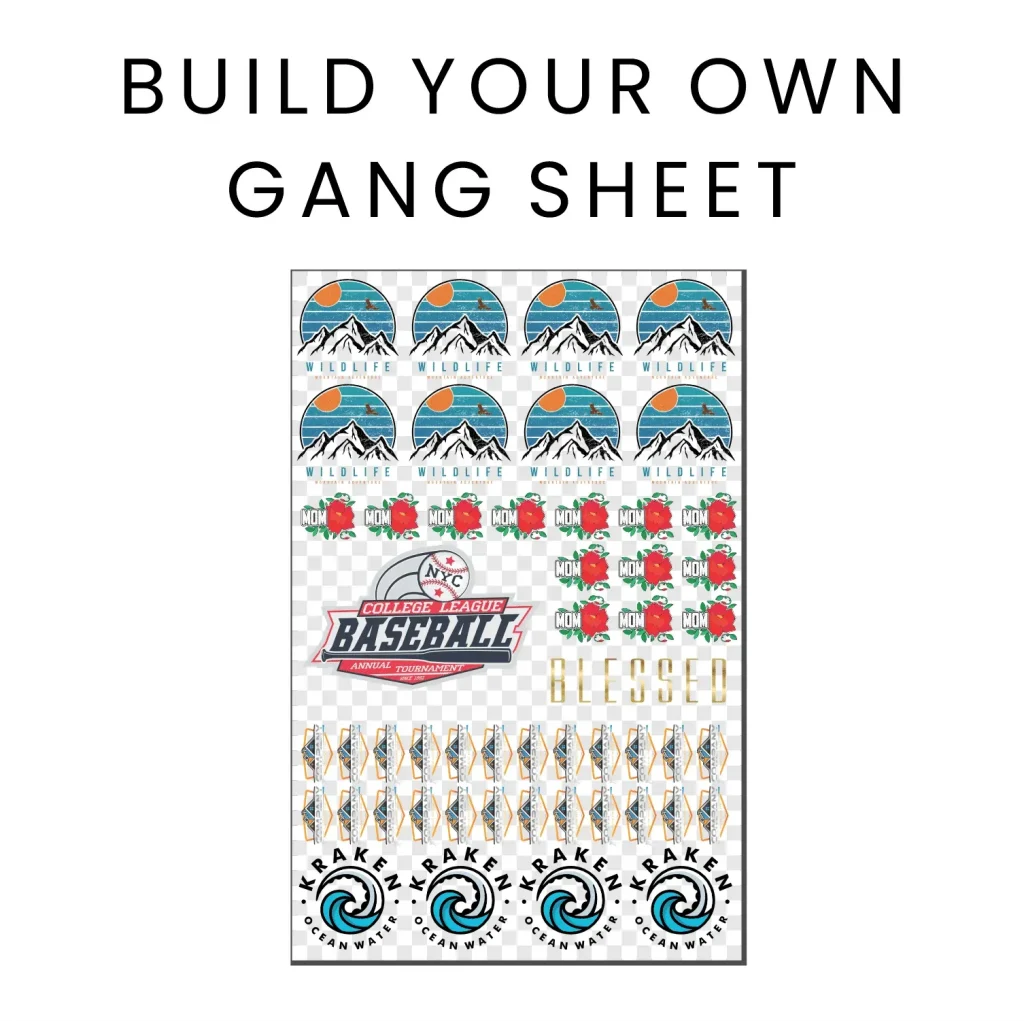

DTF gangsheet builder is transforming how apparel brands plan transfers by arranging multiple designs efficiently on a single sheet. By automating layout decisions, it minimizes waste and accelerates the setup process across runs, helping shops transition from guesswork to consistent results. This approach improves DTF printing efficiency for small run apparel production by maximizing on-sheet placement and reducing the need for manual rework. Designers can experiment with more designs per batch, knowing the software will optimize spacing, margins, and alignment for fast, repeatable results. In short, a DTF gangsheet builder turns complex orders into streamlined production, cutting costs and boosting profitability across projects.

Beyond the basics, practitioners discuss optimized multi-design sheet planning as a way to maximize the printing footprint on every batch. By thinking in terms of tiling designs and efficient production flow, shops can realize savings on small runs while maintaining vibrant color and sharp detail. Ultimately, adopting these tools helps teams boost margins with DTF by reducing waste and cutting manual steps, making each order more sustainable.

DTF Gangsheet Builder Essentials: How It Works to Cut Waste and Time

A DTF gangsheet builder is a software tool that automatically arranges multiple designs on a single DTF transfer sheet, maximizing surface use and minimizing waste. By analyzing color channels, print areas, and bleed allowances, it creates an optimal layout that reduces material waste and printer idle time. This is a cornerstone of DTF printing efficiency, especially when handling diverse designs or limited runs. For small businesses, the automation reduces manual layout work, enabling teams to scale without increasing labor costs.

With a well-tuned gangsheet, setup times drop sharply because the production file is pre-optimized for the press. As designs are packed into a single sheet, you can produce more units per batch, improving throughput on small run apparel production. The result is a tighter production flow, fewer reworks, and a smoother handoff from design to production, helping printers meet demand without sacrificing quality.

Boost DTF Printing Efficiency with Smart Gangsheet Layout Optimization

Gangsheet layout optimization is the strategic craft of placing designs to maximize printing efficiency. It considers ink laydown, color separations, and the printer’s capabilities to minimize color changes and material waste. A smart layout reduces the number of test prints and reprints, which is particularly valuable in DTF workflows where transfer sheets can be costly. It also enables quicker validation of designs before production.

As layouts improve, you’ll see direct benefits in cost savings in DTF small runs because you’re using the sheet more effectively. The optimization process also supports consistent color reproduction across shirts, which helps in maintaining brand integrity and customer satisfaction. In practice, gangsheet optimization translates into leaner runs and more predictable margins per order.

Maximize Small Run Apparel Production with Efficient DTF Practices

Small run apparel production demands flexibility and speed. An optimized DTF approach leverages templates and gangsheet arrangements to slice through setup time and avoid bottlenecks. Designers can still deliver high-quality, vibrant prints, while production teams gain a repeatable process that scales with demand. DTF printing efficiency benefits significantly when runs are modest but kept consistent.

Adopting efficient practices supports profitability by enabling rapid iteration without a price premium on per-unit costs. Customers receive customized garments faster, and shops can maintain competitive lead times even with limited batch sizes. The combined effect is stronger customer satisfaction and a more resilient business model in the DTF ecosystem.

Increase Profit Margins with DTF: From Design to Production Flow

Profitability in DTF comes from reducing losses across the entire cycle, from initial design to finished product. A streamlined gangsheet workflow allows more designs to share the same transfer sheet, reducing material waste and minimizing dye and ink consumption. This end-to-end efficiency directly supports increase profit margins with DTF by lowering cost per unit while maintaining or elevating print quality.

When production flow is synchronized, shop throughput rises and lead times shrink. This means more orders fulfilled per day without requiring additional equipment or overtime. For businesses aiming to scale, the combination of layout efficiency and automated preparation translates into healthier margins and a stronger competitive position in the market.

Cost Savings in DTF Small Runs: Reducing Waste and Setup Time

One of the clearest benefits of optimized DTF workflows is cutting waste on every sheet. By carefully planning placements and color blocks, a gangsheet builder minimizes offcuts and misprints, which directly contributes to cost savings in DTF small runs. These savings compound as you increase the number of designs that fit on a sheet and reduce the need for costly reprints.

In practice, the savings show up as lower material costs, less ink usage, and shorter production cycles. For small businesses, these efficiencies free up capital to reinvest in better designs, faster fulfillment, or expanded product lines. Implementing this approach helps maintain competitive pricing while protecting margins in a niche that is highly sensitive to cost fluctuations.

From Concept to Customer: Streamlined DTF Workflows and Gangsheet Planning

A successful DTF operation starts with concept-to-customer planning, where designs are prepared with the final transfer sheet in mind. Gangsheet layout optimization should be part of early design briefs so that color counts, print areas, and orientation fit the sheet. Proactive planning reduces late-stage changes and supports a smoother production flow, aligning creative intent with manufacturing reality.

With a mature workflow, shops can deliver accurate orders faster, improve consistency, and sustain high-quality outputs. The integration of a robust DTF gangsheet builder into daily operations helps teams stay on schedule, cut waste, and boost overall printing efficiency. This end-to-end approach is essential for sustaining growth in small run apparel production while keeping profit margins healthy.

Frequently Asked Questions

How does a DTF gangsheet builder boost DTF printing efficiency in small run apparel production?

A DTF gangsheet builder automatically arranges multiple designs on a single transfer sheet, maximizing space and minimizing waste. It reduces manual layout time and speeds prepress, which together boost DTF printing efficiency—especially valuable in small run apparel production.

Why is using a DTF gangsheet builder crucial for cost savings in DTF small runs?

By optimizing sheet usage and automating placements, a DTF gangsheet builder lowers material waste, ink consumption, and setup costs, delivering measurable cost savings in DTF small runs and benefiting small run apparel production.

How does gangsheet layout optimization with a DTF gangsheet builder help increase profit margins with DTF?

Gangsheet layout optimization packs more designs per sheet, improving transfer yield and reducing per-unit costs. This directly supports increased profit margins with DTF by cutting waste and speeding throughput.

What features should I look for in a DTF gangsheet builder to maximize DTF printing efficiency?

Seek auto-layout capabilities, precise bleed/margin controls, color-aware packing, batch exporting, and easy integration with design tools. These features drive gangsheet layout optimization and enhance overall DTF printing efficiency.

Can a DTF gangsheet builder improve the workflow from design to production for small run apparel production?

Yes. A DTF gangsheet builder streamlines the design-to-production flow by auto-arranging designs, reducing file handling, and speeding prepress, which improves efficiency in small run apparel production.

How does a DTF gangsheet builder contribute to waste reduction and cost savings in DTF small runs?

It minimizes wasted material through optimized placement and spacing, lowers setup time, and reduces ink and transfer waste, leading to cost savings in DTF small runs.

| Aspect | Key Points |

|---|---|

| DTF technology adoption | The apparel printing industry has rapidly adopted Direct-to-Film (DTF) technology, offering vibrant prints and flexibility for small runs. |

| Business challenge for small runs | For many small businesses, profitability on modest run sizes is the main challenge; turning each order into a profitable one requires efficient workflows and waste reduction. |

| DTF gangsheet builder definition | A software tool that automatically arranges multiple designs on a single DTF transfer sheet. |

| Core benefit | Optimizes design layouts on one sheet to reduce material waste, cut costs, and improve margins on small runs. |

| Impact on setup and production | Shortens setup time and streamlines production, enabling faster turnaround for small orders. |

| How it works | Automatically arranges multiple designs on a single transfer sheet, maximizing design density while preserving print quality. |

| Why it matters | A game changer for profitability, helping small businesses scale DTF offerings with consistent quality and reduced waste. |

Summary

The [DTF gangsheet builder] is a practical tool for turning small-run DTF orders into profitable jobs. By automatically arranging multiple designs on a single transfer sheet, it minimizes material waste, reduces setup time, and enhances profit margins on small runs. In practice, a DTF gangsheet builder supports a smooth design-to-production flow, helping teams go from concept to finished product with greater efficiency and consistency.