DTF gangsheet builder is transforming how studios scale production while preserving quality. In the context of DTF studio workflow optimization, this tool turns repetitive, error-prone tasks into smooth, repeatable processes. By automating layout decisions with DTF gangsheet automation, it helps manage dozens or hundreds of designs, colors, and sizes. It also supports DTF printing templates by standardizing margins, bleed, and print areas, aiding how to create gang sheets. Finally, the DTF heat press efficiency benefits from more accurate layouts and reduced waste.

Viewed through the lens of smarter production planning, this sheet-building solution reshapes how studios organize art assets, color profiles, and press settings. By adopting template-driven workflows, shops can align design-to-production timelines, minimize errors, and improve heat press throughput without adding headcount. LSI-friendly topics include asset management, color consistency, and scalable layouts that let teams respond to larger orders with confidence. As studios explore these tools, they often look for reliable ways to automate mundane tasks, accelerate setup, and ensure consistency across runs.

Maximizing Throughput with a DTF gangsheet builder

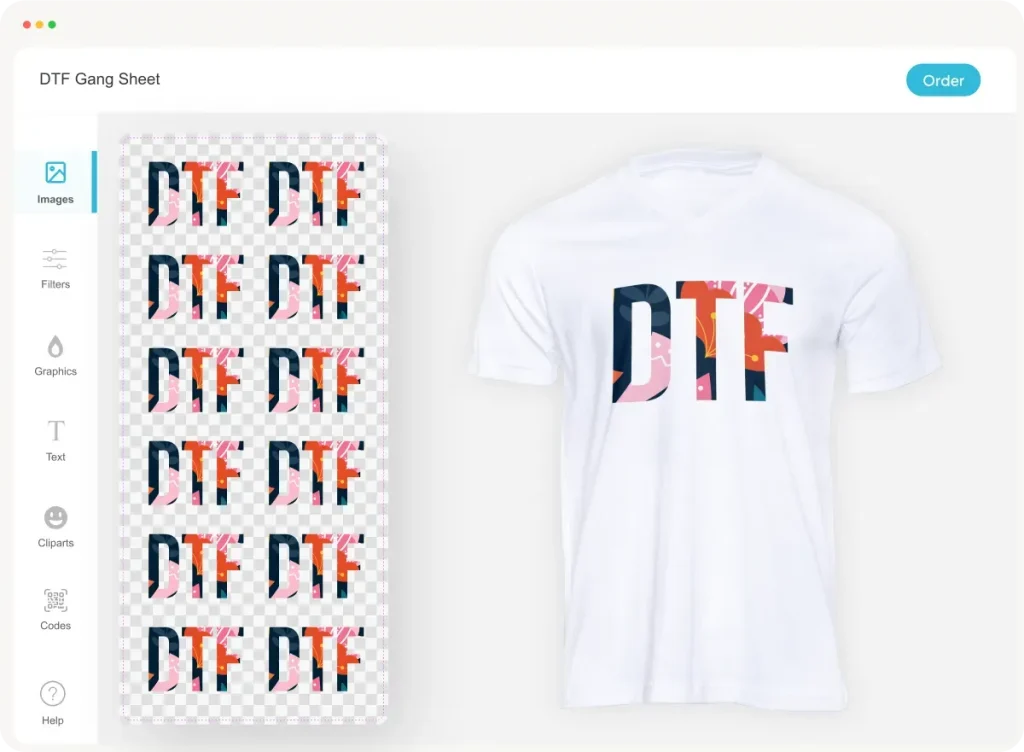

In fast-growing DTF studios, the ability to print more designs per sheet is a primary growth lever. A DTF gangsheet builder analyzes artwork, defines printable areas, margins, and color separations, and automatically tiles multiple designs onto a single gangsheet. By converting dozens of individual layouts into one optimized sheet, you reduce setup time, minimize misalignment, and increase overall prints per run.

Adopting a DTF gangsheet builder supports broader goals of DTF studio workflow optimization by centralizing assets, color profiles, and print settings. Operators work from a single source of truth, which improves consistency, shortens training time, and yields more predictable results on press.

DTF gangsheet automation: From Manual Layouts to Repeatable Production

Automation is the engine of scale in DTF production. DTF gangsheet automation eliminates manual steps in layout calculations, bleed and margin handling, and file prep, letting designers and operators rely on repeatable, machine-precise outputs.

With automation, first-pass yield improves because margins and spacing are enforced, and color separations are consistently aligned. When templates and centralized settings feed the automation, you can quickly ramp up production without sacrificing quality.

DTF Printing Templates and Standardization for Consistent Results

DTF printing templates provide a standard baseline for placement, spacing, and heat-press parameters, ensuring each sheet follows the same rules.

When templates are integrated with a gangsheet builder, you gain repeatability across runs and easier onboarding for new staff. This standardization reduces color shifts, misregistration risks, and material waste.

How to Create Gang Sheets: A Practical Guide for Scalable Production

How to create gang sheets: a practical approach begins with organized files, defined dimensions, and a plan for maximum sheet utilization.

A reliable dtf gangsheet builder will import assets, apply consistent margins, and arrange designs to maximize sheet usage, with a preview step to validate before printing.

DTF Heat Press Efficiency: Optimizing Time, Temperature, and Material Use

DTF heat press efficiency improves when layouts respect margins and when transfer parameters are standardized across designs.

By aligning gangsheet layouts with standardized templates and centralized settings, you shave seconds from transfer times and reduce material waste, boosting overall profitability.

DTF Studio Workflow Optimization: Centralized Assets and Unified Settings

DTF studio workflow optimization benefits from centralized asset management, color profiles, and unified print settings.

With a single source of truth, teams train faster, reduce production errors, and scale to larger orders while maintaining quality and predictable lead times.

Frequently Asked Questions

What is a DTF gangsheet builder and how does it support DTF studio workflow optimization?

A DTF gangsheet builder is software that arranges multiple designs onto a single sheet for heat transfer. It streamlines setup, centralizes assets, and enforces consistent margins and color layouts, boosting throughput and enabling DTF studio workflow optimization.

How does a DTF gangsheet builder enable DTF gangsheet automation for bulk orders?

The builder automatically positions designs, manages bleed and margins, and generates print-ready files. This reduces manual work and errors, delivering faster turnarounds and higher first-pass yields on bulk orders.

How do DTF printing templates integrate with a DTF gangsheet builder to improve production?

DTF printing templates provide standardized placement, spacing, and heat-press settings. When integrated with a DTF gangsheet builder, templates enable repeatable layouts and smoother handoffs between design and production.

How to create gang sheets with a DTF gangsheet builder to maximize heat transfer efficiency?

Import artwork, define printable areas, apply templates, and let the builder arrange designs for maximum sheet utilization. Use the preview to confirm margins, color placement, and heat-press timing before printing.

How can a DTF gangsheet builder improve DTF heat press efficiency and reduce waste?

By standardizing margins, aligning color layouts, and coordinating print timing, the builder minimizes waste and speeds up production. This leads to fewer reprints and more consistent results across runs.

What are best practices when using a DTF gangsheet builder to scale your studio and optimize DTF studio workflow optimization?

Define goals and KPIs; standardize templates and profiles; centralize assets; validate outputs with previews; train staff; monitor and iterate. These steps support scalable, reliable DTF studio workflow optimization.

| Key Point | Explanation |

|---|---|

| What is a DTF gangsheet builder? | Software that arranges multiple designs onto a single sheet for heat transfer, creating a gangsheet layout that maximizes prints per run. It imports artwork, defines printable areas, margins, and color separations, and outputs a ready-to-print gangsheet. Benefits include faster setup, improved consistency, and easier batch processing, enabling studios to serve more clients with the same equipment. |

| Why scaling matters | Scaling focuses on throughput, efficiency, and reliability. Manual gang layouts risk misalignment, color bleed, and waste. A reliable builder automates layout decisions and enforces spacing and margins, leading to clearer design alignment, better color matching, and faster turnaround. |

| Key benefits |

|

| Automation support | Automation drives layout calculations, bleed/margin handling, and print-ready file generation. It reduces repetitive tasks, enables focus on color optimization and client communication, and lowers human error when placing designs on sheets. Templates standardize design positions and heat settings, creating a repeatable process from design to print. |

| How to create gang sheets | Start with clear file organization. Gather all artwork, confirm dimensions and color profiles, and determine how many designs fit your printable area. A dtf gangsheet builder imports assets, applies consistent margins, automatically arranges designs for maximum sheet utilization, and provides a preview before printing to verify layout. |

| Design considerations |

|

| Best practices |

|

| Common pitfalls |

|

| ROI and long-term value | Investing in a dtf gangsheet builder yields higher throughput, reduced waste, and improved consistency. This enables more orders, shorter lead times, and scalable pricing. Long-term ROI comes from time savings, material efficiency, and happier customers with accurate, on-time shipments. |

Summary

Table above summarizes the key points about a DTF gangsheet builder and how it supports scaling a DTF studio.