DTF heat press settings are the backbone of successful Direct-to-Film transfers, shaping color fidelity, adhesion, and durability from the first press. Using a DTF temperature guide and a measured heat press time for DTF helps align expectations across different films and fabrics. These decisions tie into DTF pressure settings and the broader workflow of direct-to-film printing heat press processes. First, follow manufacturer guidelines, then test on swatches to build a repeatable workflow that works for light cotton, blends, and specialty fabrics. With a clear focus on the key variables, DTF transfer tips and best practices lead to consistent, durable results.

In other terms, this topic can be framed as film-transfer setup parameters, or the heat-press conditions that govern how well a film-based decorative layer bonds to fabric. Think of the core variables as temperature, dwell time, and clamping force, described here as substrate-friendly parameters that influence adhesion, edge sharpness, and color stability. LSI-style terms like adhesion mechanics and color fidelity under heat connect the practical steps to broader concepts in garment printing, helping search engines relate this guidance to related topics. By speaking in related terms, readers can apply the same principles across different brands and substrates, from 100% cotton to blends and performance materials.

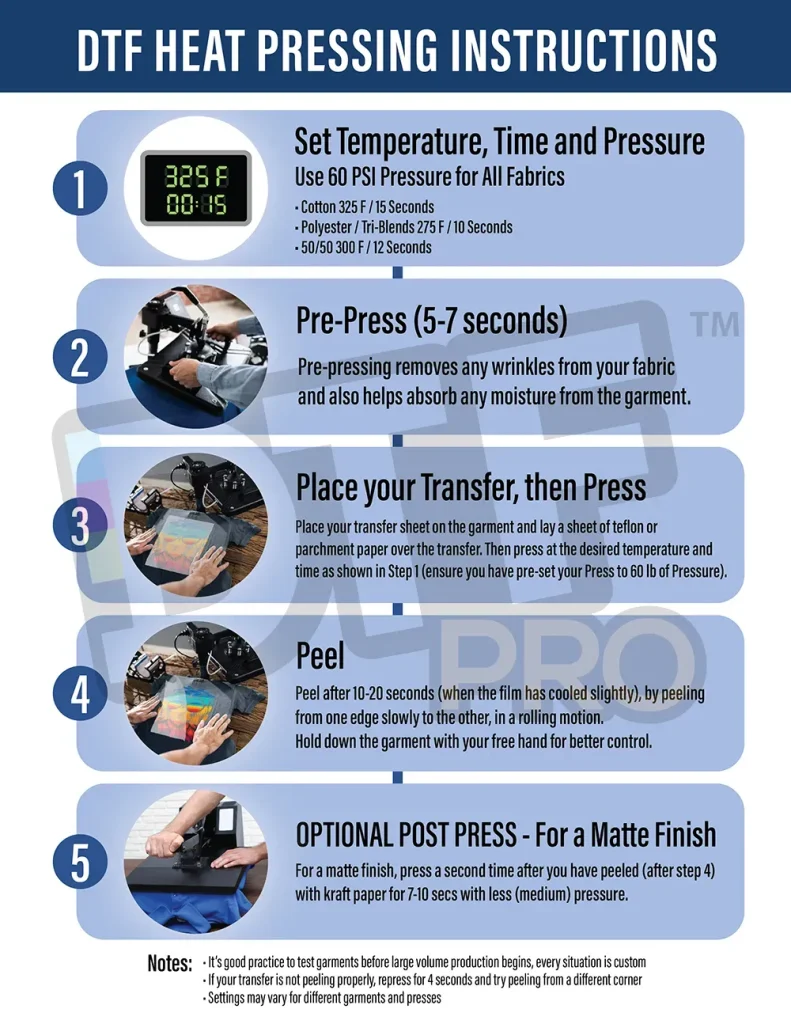

DTF heat press settings: Time, temperature, and pressure explained

DTF heat press settings revolve around three main variables: time, temperature, and pressure. Each element influences adhesion, color fidelity, and durability, and they interact in nuanced ways depending on the film, adhesive, garment, and substrate. Understanding how these factors work together helps you produce consistent transfers across batches, reducing reprints and waste.

A practical approach is to view these settings as a system rather than isolated numbers. Start with the manufacturer’s guidelines for your specific film and adhesive, then refine through small, controlled tests. Record the exact time, temperature, and pressure you used, along with notes on substrate type and garment color, so you can reproduce or adjust results with confidence.

A practical DTF temperature guide for stable transfers

A reliable DTF temperature guide is essential for vibrant colors and strong bonds. Temperature primarily affects adhesive fusion, film adherence, and pigment stability. While many processes hover around 160–170°C, the exact target can vary by film brand and fabric composition. Calibrating your heat source with an accurate thermometer helps prevent hot spots and underheating.

To dial in temperatures effectively, preheat the press area, verify platen temperature with a trusted thermometer, and adjust in small increments (5–10°C) based on test swatches. Dark garments may mask some imperfections, so color-critical transfers often require precise tuning to avoid scorching or dull prints while preserving edge sharpness.

Mastering heat press time for DTF across fabrics

Time determines how long the adhesive cures and how deeply the color embeds into the garment. Too short, and the bond may be weak; too long, and you risk scorching or distortion. The common window for DTF presses typically ranges from 8 to 20 seconds at the target temperature, but fabric weight, film thickness, and ink density can shift this range.

Different materials demand different dwell times. Cotton generally tolerates longer times than polyester blends, while heavier garments may need a touch more time for a secure bond. The key is to use small test swatches on fabrics similar to your production run, then document the exact time and color results to guide future adjustments.

Fine-tuning DTF pressure settings for edge-to-edge consistency

Pressure ensures that the adhesive contacts both the film and the fabric evenly. Inadequate pressure can lead to incomplete bonding, while excessive force can flatten fine details or cause color bleed. The goal is a consistent, even contact across the print area without crushing the design.

Practical methods include the float test to gauge resistance and using a calibrated pressure setting on your press. For thicker garments or layered fabrics, a slightly higher pressure may be necessary, while thin materials benefit from gentler, controlled force. Always distribute pressure with a protective sheet and pre-press to stabilize the surface before transferring.

Direct-to-film printing heat press: equipment and workflow essentials

Direct-to-film printing heat press requires compatible equipment and a clear workflow to maintain consistency. Use a reliable heat press with accurate temperature readouts, a silicone or teflon sheet to promote even heat transfer, and proper tape to secure the transfer. The sequence—from pre-press to final peel—must be reproducible for every batch.

A sound workflow includes prepressing the garment to remove moisture, positioning the transfer precisely, dialing in time/temperature/pressure based on film guidelines, and performing a measured dwell before evaluation. Post-press care and a documented process help you scale production while maintaining color fidelity and edge definition.

DTF transfer tips for consistent, high-quality results

DTF transfer tips center on testing, documentation, and careful handling. Keep a dedicated log that records substrate type, film brand, adhesive, and the exact settings used, along with the observed adhesion, color depth, and edge sharpness. This record becomes your reference library for repeatability across similar projects.

Key tips include using test swatches for every batch, calibrating equipment regularly, and verifying peel strategy (hot vs. cool peel) for each film. By combining precise prepress, careful parameter control, and proper post-press handling, you can achieve durable adhesion, vibrant colors, and consistent results that satisfy customers.

Frequently Asked Questions

What are the core elements of DTF heat press settings and how should I balance time, temperature, and pressure?

DTF heat press settings revolve around three variables: time, temperature, and pressure. Start with the manufacturer’s guidelines for your film and substrate, then run small test swatches to dial in the dwell time and the target temperature per the DTF temperature guide. Record the exact heat press time for DTF you used and the resulting adhesion and color so you can repeat the success. This approach builds a repeatable process across batches.

How does the DTF temperature guide influence the recommended heat press time for DTF?

Your temperature target sets the starting point for dwell time. Use the DTF temperature guide to pick a stable temperature (often 160–170°C) and then adjust the heat press time for DTF in small steps (1–2 seconds) based on adhesion and color depth. Calibrate with test swatches and log outcomes for consistency.

What are common DTF pressure settings and how can I gauge proper pressure for different fabrics?

DTF pressure settings should match fabric thickness and film weight. Use the float test and start with a medium setting, then tweak for each garment type. Thick items like hoodies require more force; thin fabrics may need less. Document the exact pressure setting you use for each combination to preserve repeatability.

How does direct-to-film printing heat press differ from standard heat pressing, and which settings matter most?

Direct-to-film printing heat press demands coordinated control of time, temperature, and pressure because the adhesion and ink behavior depend on the film and substrate. The most critical settings are the dwell time, precise platen temperature, and even pressure across the print area. Always verify with test swatches before production.

What are some DTF transfer tips for achieving sharp edges and color fidelity with heat presses?

DTF transfer tips include precise alignment, using heat-resistant tape, and choosing the right peel strategy (hot or cool) per film. Ensure even heat transfer with a silicone sheet and pre-press to remove moisture. A small library of tested settings for common films helps maintain edge sharpness and color fidelity.

How should I create a repeatable workflow using DTF heat press settings across different films and fabrics?

Create a repeatable workflow by building a settings library for each film and fabric combo, logging time, temperature, pressure, substrate, and results. Regularly calibrate your heat press and verify accuracy with a separate thermometer. Use the documented DTF heat press settings as your baseline for future projects to reduce trial-and-error.

| Aspect | Key Points | Practical Tips |

|---|---|---|

| Time | Time is the duration of heat exposure; typical 8–20 seconds; varies by film, adhesive, garment material, and ink density; test swatches; log results. | Start with manufacturer recommendations; test on similar fabrics; adjust in small increments (1–2 seconds); document outcomes. |

| Temperature | Usually around 160–170°C (320–338°F); can vary by brand; calibrate the press; preheat; adjust in 5–10°C increments based on results and substrate color. | Use a reliable, calibrated heat source; verify platen temperature with an external thermometer; start at brand recommendations; adjust as needed; use protective sheets. |

| Pressure | Aims for consistent, even contact; too little leads to weak adhesion, too much can flatten details; gauge with tests like a float test; adjust for garment thickness and film. | Use medium, even pressure; use silicone/teflon sheets; pre-press 2–3 seconds; ensure the garment is flat; avoid moving during press. |

| Interplay & Process | Time, temp, and pressure interact; higher temperature can reduce required time; higher pressure can aid adhesion at lower temperatures; substrate, fabric color, and film influence outcomes. | Follow a structured workflow: pre-press, position transfer, set parameters, press and evaluate, consider peel strategy, post-press care; maintain a log for future batches. |

| Common Mistakes / Advanced Tips | Common mistakes: skipping test swatches; mixing brands without recalibration; uneven heat; rushing dwell times. | Advanced tips: maintain a results log; test swatches for every batch; calibrate equipment; optimize for color fidelity; consider upgrades for consistency. |

Summary

DTF heat press settings are the backbone of successful transfers, guiding the optimum balance of time, temperature, and pressure to achieve reliable adhesion, vibrant color, and durable wear. Understanding how these variables interact helps you develop a repeatable process across different fabrics, films, and substrates. For best results, build a library of tested settings, log observations, and refer to a DTF temperature guide and DTF transfer tips when introducing new materials. With careful calibration and consistent testing, your DTF transfers will look sharp, wear well, and satisfy customers who expect durable, high-fidelity prints.