UV DTF films are a pivotal choice when selecting materials for direct-to-film (DTF) printing, because their performance shapes color accuracy, edge clarity, and durability. In this guide, we’ll compare UV DTF films quality indicators such as consistency in thickness and surface uniformity to help you decide. Gloss matters, and UV DTF film gloss can influence color depth and the tactile feel of the finished transfer. Durability of UV DTF films should be measured by wash resistance, light fastness, and flexibility on different fabrics to ensure reliable performance. Whether you’re looking for the best UV DTF films that fit your budget and workflow, this overview helps you compare options and explains how to choose UV DTF films with confidence.

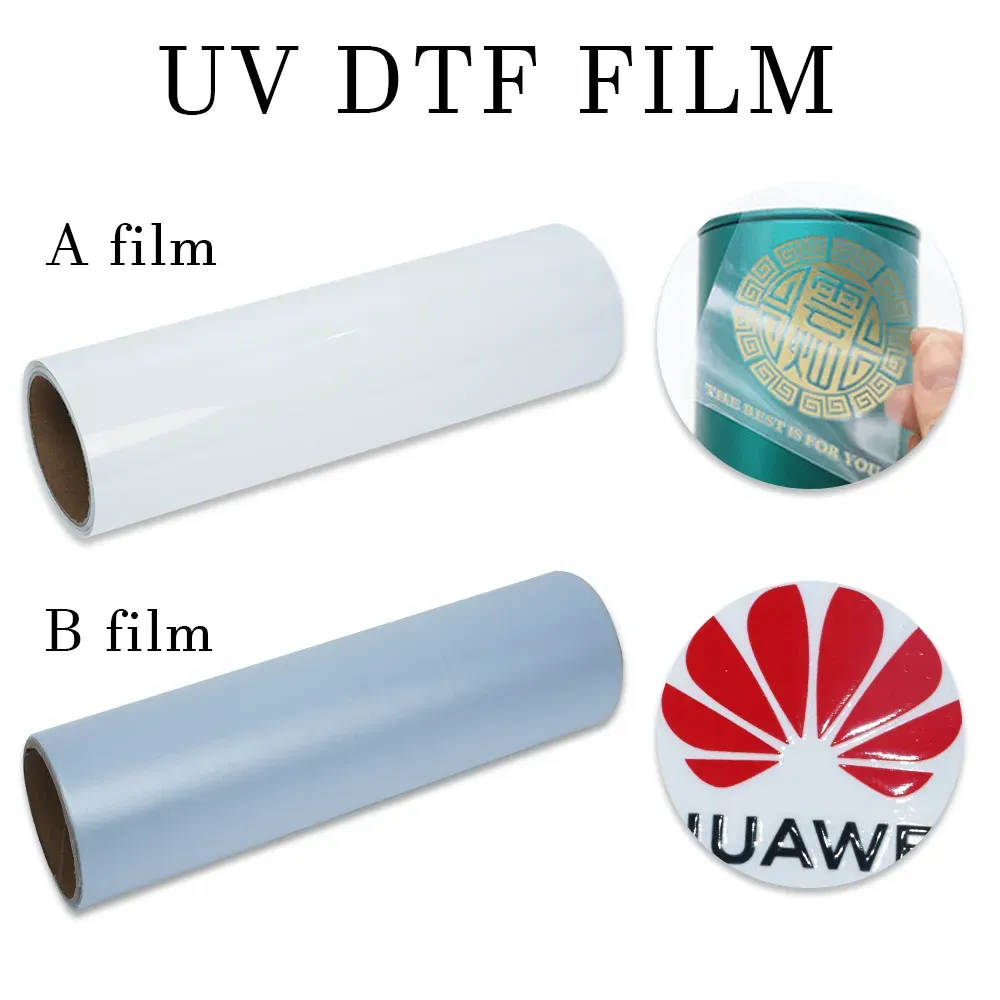

For newcomers to this technology, imagine UV-curable transfer sheets that carry graphics from printer to fabric through heat and pressure. These UV-ink compatible media serve as the carrier that bonds designs to textiles or plastics after a cure. Evaluating such media involves checking substrate compatibility, finish options, and wash durability to ensure reliable results across runs. Using LSIs, we connect related concepts like photo-transfer films, UV-curable print media, and heat-transfer coatings to broaden understanding while keeping the focus on performance.

1) UV DTF Films: Understanding Quality and How It Impacts Your Prints

When evaluating UV DTF films, the most immediate consideration is overall UV DTF films quality. The film’s substrate, adhesive layer, and top coat influence color fidelity, edge definition, and print stability after curing. A quality film minimizes color bleed and feathering and maintains detail through washing and wear. Paying attention to these factors helps ensure that your designs look consistent from batch to batch.

Quality is not just the paper; it’s the entire multi-layer system. Uniform thickness, clean edges, consistent curl, and burr-free coatings all contribute to predictable results across runs. If you test a sample and notice misregistration or color shifts, that’s often a sign the UV DTF films quality varies between batches, which can lead to waste and rework on commercial orders.

2) The Role of UV DTF Film Gloss in Color Vibrancy and Detail

Gloss level directly affects how light interacts with the print. A high-gloss UV DTF film can boost punchy color and crisp highlights, which is ideal for bold designs and photography-like imagery. However, gloss can also emphasize surface dust or fingerprints, so choice should match the intended display conditions.

A mid-gloss or balanced finish often provides a reliable compromise between color depth and tactile feel, reducing glare while preserving detail. Consistency of UV DTF film gloss across batches is crucial for multi-item runs, especially when front-and-back designs or panels must match in appearance.

3) Durability of UV DTF Films: Ensuring Wash and Wear Longevity

Durability of UV DTF films depends on adhesive chemistry, ink compatibility, and the curing profile you use. A durable film resists washing, rubbing, and UV exposure, helping colors stay vibrant and the bond to the substrate remain intact over time. This longevity is essential for apparel, accessories, and items that see frequent use.

To evaluate durability, look for independent wash tests and abrasion data, and verify compatibility with your printer, ink system, and heat-press or curing method. A film marketed as durable won’t perform as well if your workflow uses an incompatible cure time or temperature, so align curing settings with the film’s specifications for best results.

4) How to Choose UV DTF Films: A Practical, Step-by-Step Guide

Begin by clarifying your substrate and garment types, then assess ink compatibility, curing method, and preferred gloss level. This is where how to choose UV DTF films becomes a structured decision process, helping you avoid costly misfires on color, adhesion, or durability.

Create a compact test matrix: print sample designs on your typical fabrics, measure color targets, test adhesion after cure, and perform short wash cycles. Build a decision checklist that includes edge quality, thickness uniformity, curl, storage stability, and batch-to-batch consistency to guide future purchases.

5) What Makes the Best UV DTF Films for Commercial Runs

For high-volume production, consistency is essential. The best UV DTF films deliver predictable color, stable gloss, and durable adhesion across a range of substrates and lighting conditions. Look for films with proven performance in wash tests and real-world durability claims, and consider long-term supply stability for ongoing runs.

Factor in handling, storage, and support from the supplier. The best UV DTF films balance cost and yield, offering easy workability, robust shelf life, and clear guidance on cure settings. When a film delivers both reliability and efficiency, it translates into faster throughput and fewer reprints across commercial projects.

6) Common Pitfalls and Pro Tips When Selecting UV DTF Films

Common pitfalls include assuming all UV DTF films are the same, neglecting substrate interaction, or choosing a gloss level that clashes with fabric color or texture. Some films may delaminate on stretch fabrics or dyebath-treated textiles, so it’s important to test on your specific substrates.

Pro tips: run small, controlled tests in your actual production workflow, calibrate curing times to your lamp and ink, and store films properly to preserve adhesive properties. Maintain detailed records of batch numbers, cure settings, and fabric types to ensure traceability and consistency across future runs.

Frequently Asked Questions

How does UV DTF films quality affect color accuracy, edge detail, and adhesion?

UV DTF films quality directly affects color accuracy, edge definition, and adhesion. High-quality films preserve vibrancy after curing, deliver sharp edges, and bond reliably across fabrics. To verify, look for uniform thickness, clean edges, and compatibility with your printer and inks, then run a small test batch on target fabrics.

What role does UV DTF film gloss play in finished prints, and how should you choose the level of UV DTF film gloss?

UV DTF film gloss influences color richness and texture. High-gloss films deliver punchy colors and sharp highlights; mid gloss offers a balanced look; low gloss reduces glare but may show dust more. For consistency, ensure gloss is uniform across batches and test gloss levels with your designs on the target fabrics.

What factors influence the durability of UV DTF films during wear, washing, and sunlight exposure?

Durability depends on adhesive chemistry, ink compatibility, and the curing process. Durable UV DTF films resist washing, abrasion, and UV fading, stay flexible on stretch fabrics, and maintain adhesion under temperature cycles. Verify durability with wash tests and confirm compatibility with your printer, inks, and curing method.

What are the best UV DTF films for different substrates, and how do you determine the best UV DTF films for your workflow?

Best UV DTF films depend on substrate, ink system, and curing method. For apparel like cotton, prioritize strong adhesion and wash durability; for synthetics, favor flexibility and UV resistance. Use supplier data, run pilot tests on representative substrates, and compare results across gloss, adhesion, and durability.

How to choose UV DTF films: what criteria matter for quality, compatibility, and durability?

How to choose UV DTF films starts with defining end use and substrate, then evaluating film quality, consistency, adhesive compatibility, and ink/curing compatibility. Check dimensional stability, durability claims, and batch data, and always perform a small-scale test before full production.

How can you balance UV DTF film gloss with the durability of UV DTF films to maintain color and flexibility?

Balancing UV DTF film gloss with durability involves matching the gloss level to design goals while ensuring the adhesive and topcoat support long-term performance. Choose a gloss that suits the substrate, verify top-coat compatibility with your inks and curing system, and validate through testing across multiple washes and flex cycles.

| Topic | Key Points (Summary) |

|---|---|

| Introduction | DTF printing quality hinges on film choice; UV DTF films enable vibrant color, clean details, and durable finishes. The guide covers quality, gloss, and long-term durability to help you decide for commercial runs or personal projects. |

| What are UV DTF Films? | Transfer sheets made for UV-curable inks; used to print images that are transferred to textiles, plastics, or other substrates. They typically combine a specialized adhesive coating, a durable top layer, and a UV-friendly film substrate, explaining variability in quality, gloss, and durability. |

| Why UV DTF Film Quality Matters | Quality affects color accuracy, edge sharpness, and transfer longevity. High-quality films tend to preserve vibrancy, keep edges crisp, provide reliable adhesion across fabrics, resist yellowing/cracking, and reduce delamination. |

| Gloss: What It Is and Why It Matters | Gloss describes the film’s reflective surface after cure. High gloss yields punchy colors and sharp highlights; medium gloss balances visibility of dust and can feel softer on fabric; low/matte reduces glare but may show dust more. |

| Durability: How Long Will It Last? | Durability comes from adhesive chemistry, ink compatibility, curing, and end-use. Durable films resist washing and abrasion, resist UV fading, stay flexible on stretch fabrics, and maintain adhesion under temperature changes. Check compatibility with printer, ink system, and cure method. |

| How to Choose the Best UV DTF Films | Criteria include film quality/consistency, gloss compatibility with target look, adhesive compatibility, ink and curing compatibility, dimensional stability, and overall durability expectations. |

| Practical Tips for Using UV DTF Films | Test before large runs; calibrate curing to ink and film; optimize heat-press parameters; consider substrate variations; store films properly to prevent changes in adhesive properties or curling. |

| Common Myths About UV DTF Films | Not all films perform the same; higher gloss does not guarantee better durability; UV DTF can work on a range of fabrics—always test for your materials. |

| Case Studies: Real-World Outcomes | Case A: high-gloss film produced deeper reds and sharper blues with excellent wash durability. Case B: mid-gloss performed well on textured fabrics, reducing fiber visibility while maintaining readability. Case C: durable film retained color and flexibility on stretch fabrics after multiple washes. |

| Quality Assurance Checklist | Visual inspection for curl and defects; quick adhesion test after cure; color check against targets; wash testing; document batch numbers, cure times, and fabric types for traceability. |

| Conclusion | Selecting UV DTF films is a multi-criteria decision. It’s not just about gloss or adhesion; it’s about how these properties work with your printer, inks, fabrics, and curing setup to deliver consistent, high-quality transfers. |

Summary

Conclusion: Selecting UV DTF films is a multi-criteria decision. It’s not just about gloss or adhesion; it’s about how these properties work with your printer, inks, fabrics, and curing setup to deliver consistent, high-quality transfers.